Comparison table of different Advanced Seam Tracking and Vision Systems,

General Advice for Choosing Seam Tracking and Vision Systems:

-

Assess Your Welding Needs: Choose a system based on the complexity of the weld, material type, and production volume. High-precision applications (like aerospace or automotive) benefit from more advanced 3D vision systems, whereas simpler welds may only require basic seam tracking.

-

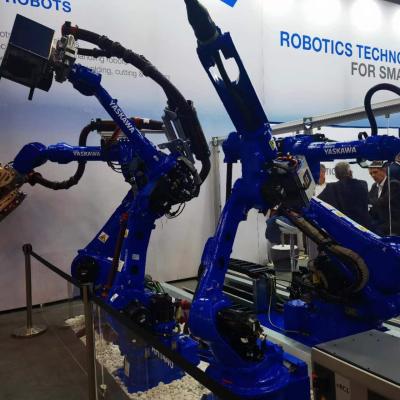

Integration with Existing Equipment: Consider systems that are compatible with your existing robotics or welding systems. If you're already using a specific brand of robot (e.g., FANUC, Yaskawa), choosing a seam tracking system from the same provider can simplify integration.

-

Software Customization: Ensure that the software provided is easy to use and allows for custom programming if your welding process involves non-standard components or geometries.

-

Operator Training: Invest in training for your operators, especially for more complex systems like laser seam tracking or 3D vision. The more advanced the system, the steeper the learning curve, but the payoff in precision and efficiency is significant.

-

Long-term Maintenance: Choose systems with good after-sales support and a reliable maintenance program. Seam tracking systems with vision technology require regular calibration and updates to ensure optimal performance.

| System/Technology | Provider | Software | Applications | General Advice |

| MotoEye LT Seam Tracking | Yaskawa Motoman | MotoSim EG-VRC | Arc welding, precision seam tracking, multi-axis welding | Ideal for complex weld geometries requiring high precision. Great for integration with Yaskawa robots. |

| TAST (Through-Arc Seam Tracking) | Fanuc Robotics | ROBOGUIDE | MIG and TIG welding, simple seam tracking | Best suited for standard seam tracking in less complex environments. Cost-effective for simpler welds. |

| Servo-Robot i-Cube™ 3D Vision System | Servo-Robot Inc. | Servo-Robot Control Software | Laser welding, hybrid welding, robotic welding | Perfect for high-precision tasks, especially in laser and hybrid welding applications. Invest in training for operators. |

| Laser Seam Tracking System (LSTS) | Meta Vision Systems | MetaLaser™ Vision System | Laser welding, MIG/TIG welding, steel and aluminum | Best for applications requiring high accuracy and real-time adaptive welding. Works well in heavy-duty industries like shipbuilding and automotive. |

| ArcTrack | SKS Welding Systems | SKS Welding Software | MIG/MAG welding, arc welding | Great for arc welding operations requiring consistent tracking in mass production. |

| iRVision 3D Seam Tracking | Fanuc Robotics | FANUC iRVision | Arc welding, MIG/TIG, seam tracking with robot integration | Easy integration with FANUC robots and good for industries like automotive. Suitable for companies already using FANUC systems. |

| ABIROB A500 Seam Tracking | ABICOR BINZEL | WeldGuide III | MIG welding, heavy steel fabrication | Reliable for high-amperage and large-scale welding, commonly used in shipbuilding and heavy manufacturing. |

| Cognex VisionPro Seam Tracking | Cognex Corporation | VisionPro Software | Automated welding, precision fabrication | Flexible and scalable, recommended for manufacturers needing a highly customizable vision solution. |

| Smart Laser Vision System | IPG Photonics | LightWELD Vision System | Laser welding, precision welding of thin metals | Excellent for laser welding applications requiring speed and precision, particularly in thin sheet metals. |