Main Solutions: We offer a variety of welding solutions for different metal types and welding processes, including MIG, TIG, and laser welding. Our services cover welding cells, equipment, and accessories to ensure efficient and high-quality results for all your welding needs.

|

Welding Type |

Brands & Models |

Major Components |

General Notes |

|

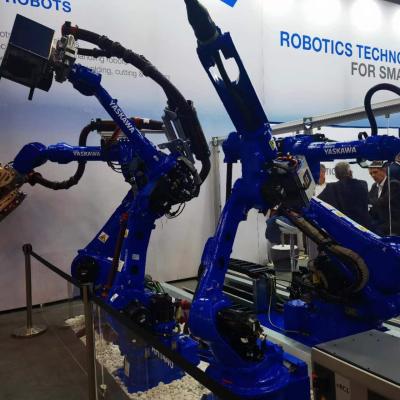

Arc Welding Robots

MIG/MAG, TIG, Laser |

Here is detailed comparison of specifications MOTOMAN AR series robots |

Yaskawa YRC1000 controller, Power Source

Welding Gun

Chiller

|

Pros: High precision, consistent quality, suitable for various metals Cons: High initial cost, requires programming and setup Common in automotive and heavy machinery industries |

| Spot Welding Robots |

|

Yaskawa YRC1000 controller, Power Source:

Welding Gun

|

High electrodes wear due to constant use |

Types of Welding

Here is a comparison of MIG, TIG, and Laser welding in table form:

| Aspect | MIG Welding (Metal Inert Gas) | TIG Welding (Tungsten Inert Gas) | Laser Welding |

| Heat Source | Electric arc between a consumable wire electrode and the workpiece | Electric arc between a non-consumable tungsten electrode and the workpiece | Focused laser beam generates heat |

| Shielding Gas | Uses inert gas (Argon, Helium) or gas mix | Uses inert gas (typically Argon) | Optional, sometimes uses an inert gas |

| Filler Material | Consumable wire acts as both electrode and filler metal | Can use filler rod, but not always necessary | Can use filler material or weld without it |

| Precision | Moderate precision, suitable for thicker materials | High precision, best for thin materials and intricate work | Extremely high precision, ideal for detailed and small work |

| Welding Speed | Fast, making it efficient for larger, thicker materials | Slower, requires more skill and control | Very fast, ideal for high-volume production |

| Material Thickness | Best for medium to thick materials | Best for thin to medium materials | Suitable for a wide range of thicknesses |

| Material Types | Works well on steel, stainless steel, aluminum, and other metals | Best for stainless steel, aluminum, copper, and thin metals | Can weld various metals, including dissimilar ones |

| Difficulty Level | Easier to learn and automate | Requires a high level of skill and control | Complex setup and requires advanced technology |

| Heat Input | High heat input, can lead to distortion on thin materials | Lower heat input, reduces distortion on thin materials | Focused heat input, minimal distortion |

| Cost | Relatively low cost for equipment and materials | Moderate cost, especially for skilled labor | High cost due to advanced equipment |

| Application | Used for general fabrication, automotive, and heavy industries | Used for precision welding in aerospace, automotive, and artistic work | High-precision industries, medical, automotive, and electronics |

| Portability | Equipment is portable and widely available | Less portable due to specialized equipment | Typically stationary, requires large equipment |

| Yaskawa Robots | MOTOMAN AR1440, AR2010, AR3120, MA1440 | MOTOMAN AR1440, VA1400 | MOTOMAN MC2000, MOTOMAN YLS |